Integrated Options

- Vision Guidance: Vision Guidance provides an efficient and versatile solution for precision robotic guidance.

- Force Guidance: Force Guide delivers fast, tactile feedback to guide robots for high-precision and high-performance parts placement.

- Flex Parts Feeding Systems: IntelliFlex by Epson delivers a high-performance part feeding solution that is easy to setup and can accommodate a wide variety of parts.

Brands & Series

Yaskawa's Smart Pendant software version 2.1

Manufacturers across a wide variety of industries are realizing the value of investing in user-friendly robotic automation. Facilitating this utilization is the Yaskawa Smart Pendant – an intuitive pendant interface that requires minimal robotics training.

Discover more about gaining powerful robot capability via easy control using the Yaskawa Smart Pendant. Building on prior release updates, software version 2.1 provides highly beneficial improvements for optimized application management. Topic highlights:

- Brief Smart Pendant overview

- Quick review of past software releases

- Detailed discussion of new features:

- Classic Interface view

- YRC system software updates

- Basic concurrent job support

- 3D viewer improvements

- Yaskawa Install Package (YIP) enhancements

- Usability improvements

- New partner kits, ready to use with Yaskawa robots

Series: EP, GP, HC, HP, MotoMini, PH, SDA, MH, SG, SIA, UP, AR, GA, HC Welding, SP, MPK, MPL, MPP, MYS, PL, EPX, MHP, MPX

Vision Guide

Integrated vision guidance with easy configuration and calibration.

- Integrated solution designed for vision guidance

- Wizard-based calibration solutions

- Fast development with point-and-click interface

- Combination robot/vision simulator

- Low-cost system for multi-camera applications

Designed for vision guidance applications, Epson Vision Guide makes precision robotic guidance easy to use. Fully integrated within the Epson RC+® development environment for easy configuration and calibration, this intuitive solution features a point-and-click interface that makes it simple for users of all levels. It also features wizards and auto calibration methods, plus a combination robot/vision simulator for rapid offline testing. With a single point of support for both robots and vision guidance, Epson Vision Guide allows for fast development and simplified maintenance. An efficient and versatile solution, it also includes tools to address inspection, gauging and barcodes.

- Integrated vision guidance solution ― designed with tools specifically made for vision guidance applications

- Wizard-based setup ― for fixed and mobile camera/robot calibration; with auto calibration and no-touch calibration solutions

- Fast development with point-and-click interface ― fully integrated into the Epson RC+ development environment

- Combination robot/vision simulator ― for rapid offline testing and development

- Low-cost scalable system ― accommodates multi-camera applications

- High-precision parts placement ― features built-in kinematic equations and advanced algorithms

- Powerful vision tools ― full suite of options for a wide variety of applications and industries

- Intuitive operation ― easy to learn and use for entry-level to advanced users

- Powerful throughput ― CPU and vision processing runs parallel with Epson robot controllers

- Expansive camera support ― supports up to 4 GigE and 2 USB cameras, up to 10MP monochrome cameras and 5MP color cameras

IntelliFlex Feeding System

High-performance parts-feeding solution with easy integration.

- High-performance parts-feeding solution ― powered by Epson robots, IntelliFlex Software, and Vision Guide

- Simple setup and configuration ― fully integrated with Epson RC+ Development Software

- Point-and-click interface ― helps reduce the typical development time required for advanced applications

- Flexible parts handling ― four feeder sizes; supports parts from 3 to 15 mm, 5 to 40 mm, 15 to 60 mm and 30 to 150 mm

- Quick parts changeover ― feeder offers easy setup to accommodate different parts to help reduce the total cost of ownership

Powered by Epson® robots, IntelliFlex Software, and Vision Guide, the IntelliFlex Feeding System delivers a simplistic feeding solution to accommodate a wide variety of parts. Integrated with Epson RC+® Development Software, the IntelliFlex Feeding System offers easy setup and configuration. Its point-and-click interface helps reduce the typical development time required for advanced applications. Available in four feeder sizes, it accommodates parts ranging from 3 mm to 150 mm. Intelligent auto-tuning offers fast setup for flexible parts changeover and, multi-axis vibration technology provides optimized parts control and singulation.

- High-performance parts-feeding solution ― powered by Epson robots, IntelliFlex Software, and Vision Guide

- Simple setup and configuration ― fully integrated with Epson RC+ Development Software

- Point-and-click interface ― helps reduce the typical development time required for advanced applications

- Flexible parts handling ― four feeder sizes; supports parts from 3 to 15 mm, 5 to 40 mm, 15 to 60 mm and 30 to 150 mm

- Quick parts changeover ― feeder offers easy setup to accommodate different parts to help reduce the total cost of ownership

- Compatible with a wide range of parts ― supports simple to complex parts, as well as delicate materials

- Smart auto-tuning ― automatically adjusts the feeder parameters for new parts setup

- Unique directional vibration capabilities ― multi-axis vibration technology for optimized parts control and singulation

- Backlight options ― red, green, blue, white and infrared available

- Tray configuration options ― ESD, anti-static and anti-rolling available

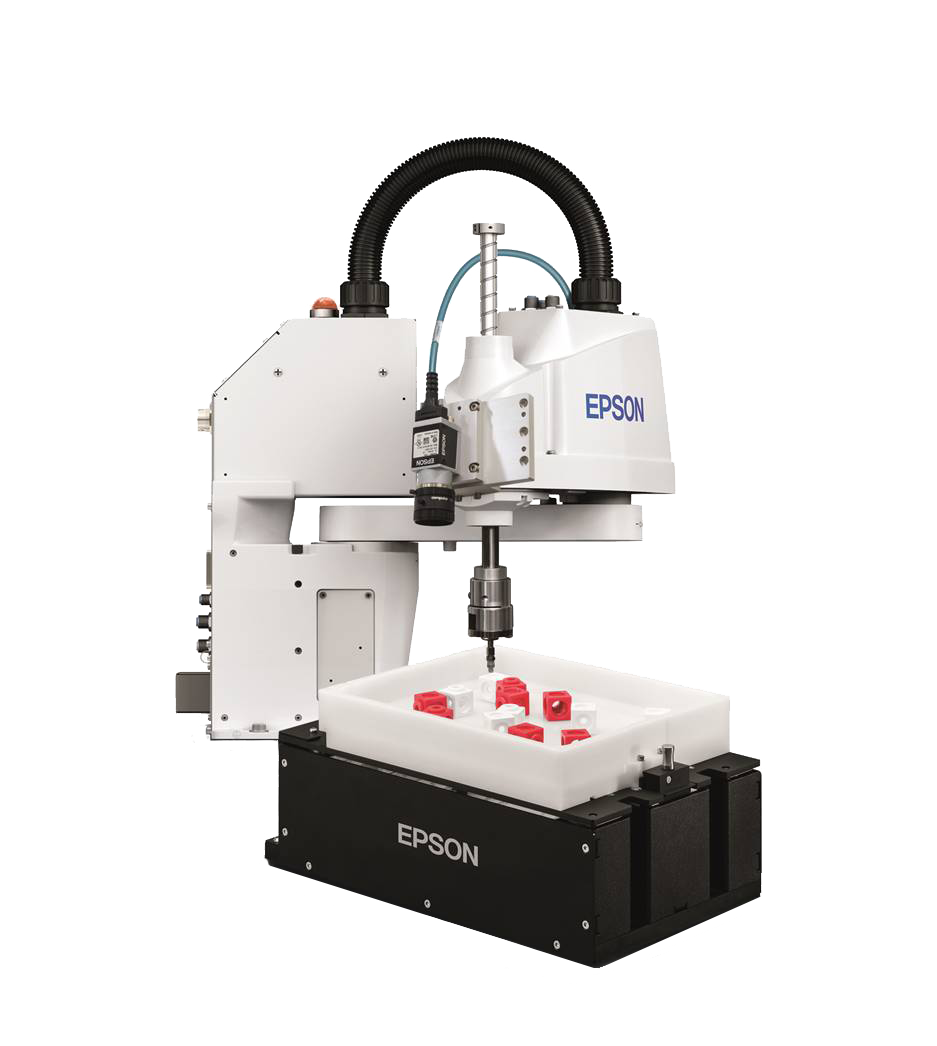

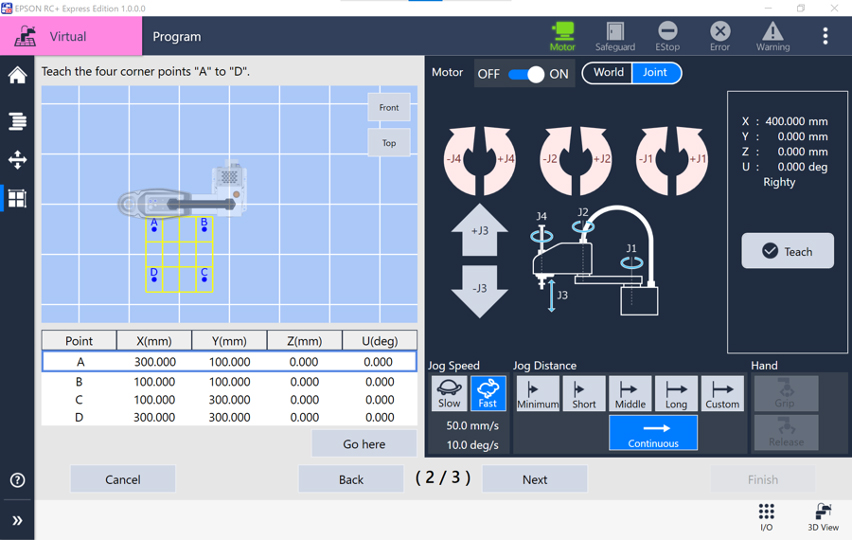

RC+ Express

No-code, easy-to-use robot teaching environment.

- Get up and running fast — with a simple, visual-based teaching environment built for new users with little to no programming experience

- Easy to use — features a simple-to-follow, block-style format with the power and flexibility of a scripted-text programming language

- Simple to navigate — clear, intuitive, visual user interface makes it easy to learn and manage key functions like jogging, gripper control and motion

- Common application templates included — quickly create common pick-and-place, palletizing and depalletizing applications with ready-to-use template programs and tutorials

- Develop applications virtually — built-in 3D simulator lets you conveniently program and fine-tune applications before hardware setup