Reliable, Easy-to-use Level Instrumentation, Designed with You in Mind

Our wide range of devices for liquids and solids measurement covers the whole spectrum from basic point level detection to challenging continuous level, interface, and volume measurement, even in extreme conditions. Use our level measurement technologies to optimize your processes, plan for maintenance, and anticipate and correct issues before they become problems.

Level Measurement Technologies

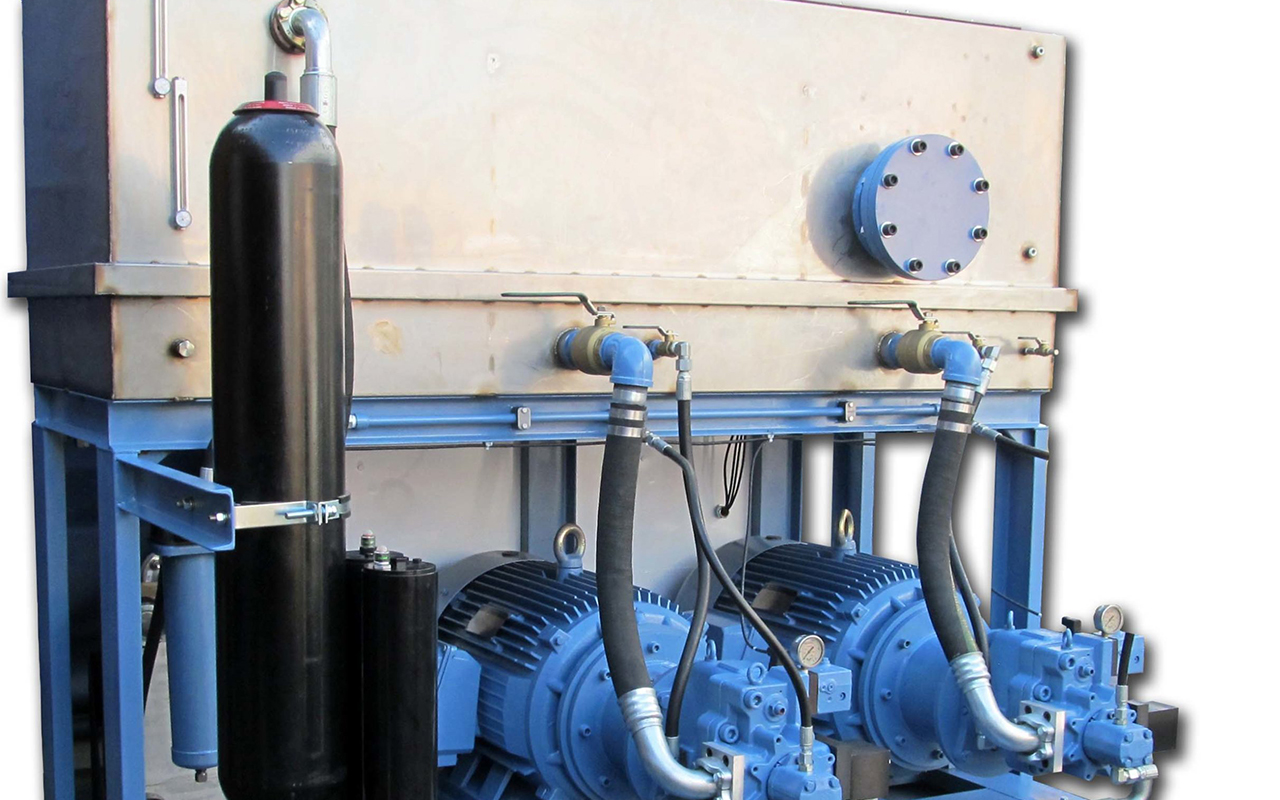

Differential Pressure Level Measurement

Differential Pressure (DP) Level Measurement uses pressure readings and specific gravity to output level. DP Level is a common measurement technique that is used in a wide variety of applications. Solutions include standard transmitter connections and integrated transmitters with direct or remote mount seals that can be configured in tuned, balanced, and electronic systems. Additional Wireless options are also available.

Reduce Maintenance, Increase Safety and Optimize Your Process

Using radar frequencies, guided in a probe going into the monitored vessel, guided-wave radar level measurement provides continuous, reliable measurements with high accuracy. The radar wave being guided by the probe, the wave energy remains high which allows measurement even in harsh conditions.

Reliable, Maintenance Free and Easy Installation

Magnetic level instrumentation provides a robust, low maintenance measurement solution across many industries including oil and gas, petrochemical and power. Magnetic Level indicators and level gauges may be used as a replacement for sight glasses, and can also provide redundant measurement when used alongside other technology such as guided wave radar.

No Maintenance, No Calibration, Extremely Versatile

Impact Automation provides laser-based distance measuring used in process control systems. An on-board microprocessor calculates distance by multiplying the speed of light by the time it takes for a laser pulse to travel from the instrument to a target and back.