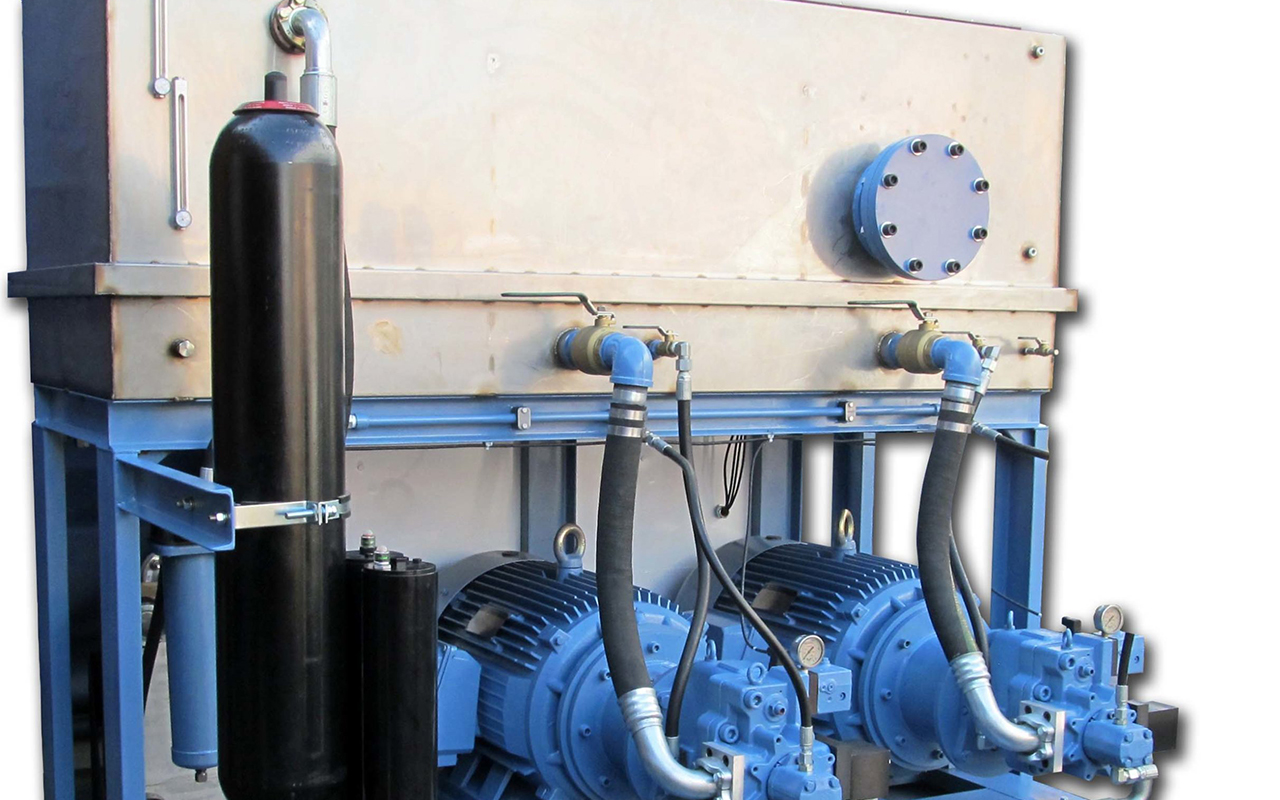

Achieve Precision Flow Measurement and Process Control

Flow Measurement is the process of measuring fluid in your plant or industry. You can measure flow through a variety of different devices such as Coriolis, differential pressure, vortex, magnetic, ultrasonic, turbine and positive displacement meters.

Reduce project complexity with our integrated service approach that includes a single point of responsibility from project conception to commissioning & support to provide complete analytical solutions.

Flow Measurement Technologies

Superior Mass Flow and Density Measurement

Impact Automaiton provides a breadth of products that are tailored to your application needs. Our Coriolis flow meters are composed of a sensor, which contains the measurement tubes, and transmitter, which displays the outputs and allows the meter to be configured to your process. Additionally, our sensors, transmitters, and software options that provide the ultimate solution for your most critical flow measurement needs.

Improve Productivity with DP Flow Measurement

As one of the most common technologies for measuring flow, differential pressure (DP) flow has a long history of achieving high accuracy and durability. This measurement technology enables compensated flow, pressure, and temperature readings from a single flowmeter solution, in some cases eliminating the need for impulse lines. Our flowmeters can be delivered pre-configured, leak tested, and ready-to-install, reducing installation time and costs while increasing overall plant productivity.

Advantages of Magnetic Flow Meters

Magnetic flow meters, also known as electromagnetic flow meters or mag meters, are often selected because they are obstruction less, cost-effective, bi-directional, and provide highly accurate volumetric flow measurement. A range of liner materials, electrode options and line sizes accommodate a wide variety of process applications. For aggressive high noise applications, look to our Slurry Platform for optimum performance.

Thermal mass flow meter technology utilizes the relationship between flow rate and cooling effect for direct measurement of mass flow. With no moving parts and minimal invasiveness, thermal flow meters provide a highly repeatable, accurate, low cost, easy to install solution for air and gas flow measurements.

In Water/Wastewater

The water and wastewater industry is another key segment driving thermal flowmeter success. Thermal flowmeters have established themselves in this industry and are a replacement choice for traditional technologies such as differential pressure, as they do not introduce pressure drop into the process flow and require less maintenance.

One of the more common wastewater treatment applications is the measurement of the air/oxygen gas used to promote the secondary treatment of sludge. Careful measurement ensures that this step is conducted within ideal parameters, and that no energy is unnecessarily wasted in pumping more air or oxygen than the process requires.

Further downstream within a treatment plant, thermal flowmeters can be found in distribution pipes and aeration basins. And, on heading toward the output side, the decomposed sludge is exposed to anaerobic treatment using other specific bacteria chosen for this purpose. The result of this step is the production of water and a mixture of gases, primarily carbon dioxide and methane, which thermal meters can measure. Methane, also called digester gas or biogas, is a growing source of a type of renewable energy. It has come into use to power on-site plant operations, and is also available as a commercial product.

Ultrasonic Flow Meters Provide Best in Class Flow Measurement Accuracy

Impact’s Gas and Liquid Ultrasonic Flow Meters provide higher accuracy, greater rangeability, advanced flow meter diagnostics, with no moving parts practically eliminating pressure loss common to other types of flow measurement devices. This advanced ultrasonic measurement technology can be applied to custody transfer, allocation measurement, check metering, leak detection and inventory control applications.

Advantages of Vortex Technology

Vortex flow meters offer many advantages for flow measurement including easy installation without impulse lines, no moving parts to maintain or repair, less leak potential and a wide flow turndown range. Vortex meters also offer very low power consumption, allowing for use in remote areas.

Additionally, Vortex meters are unique in that they can accommodate liquids, gasses, steam and corrosive applications. Vortex flow meters are also able to withstand high process pressures and temperatures.