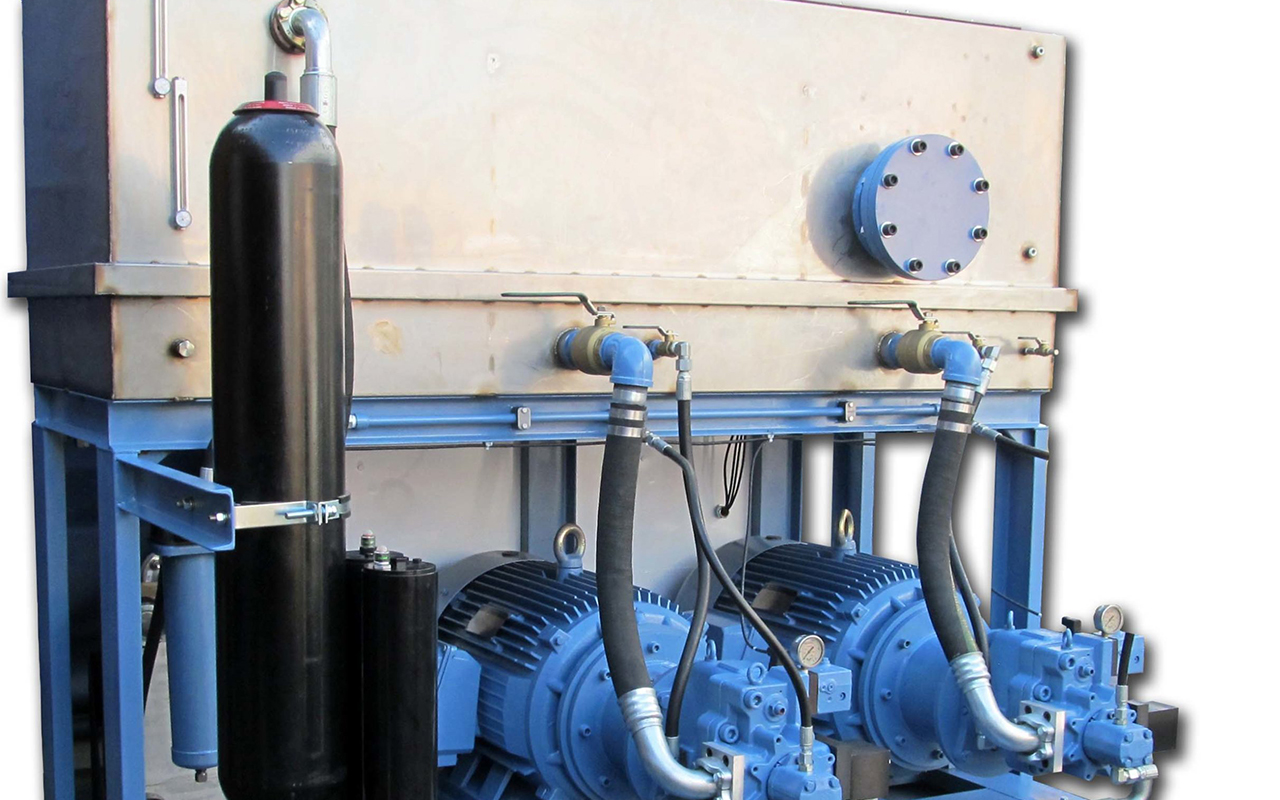

Welding

Yaskawa Welding and Cutting Robots

Yaskawa offers solutions for arc welding, spot welding and cutting. With reaches from 700 to 3000mm, we offer a welding robot for any applications.

Series: AR, GA, SP and HC Collaborative

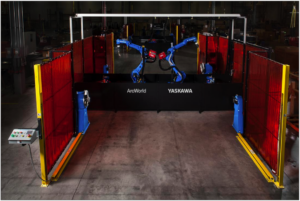

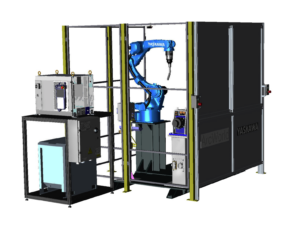

ArcWorld Systems - Pre-Engineered and Custom Designed Systems

A World of Welding Possibilities

Yaskawa Motoman’s ArcWorld® robotic welding systems are pre-engineered, pre-assembled and shipped ready to weld – delivering the most flexible and cost-effective options to integrate robotics into your welding processes. ArcWorlds can be configured with multiple robots, a heavy-duty positioner or servo-controlled external axes for coordinated motion.

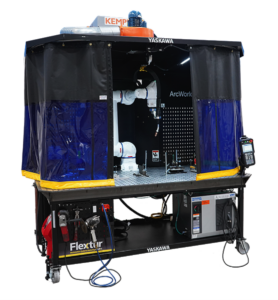

ArcWorld Compact Cells

Yaskawa offers a variety of compact, pre-configured welding cells. Systems include the ArcWorld HC Collaborative, ArcWorld LC, ArcWorld RS and ArcWorld HS. All systems utikiza a single robot, using as little as 1.4 square meters of floor space.

Brands & Series

ArcWorld 50 Series - Robust Automation for Smaller Parts

ArcWorld 200 and 500 Series - Flexble Workcells for Small to Medium Parts

ArcWorld 1000 Series - High Throughput for Medium-Sized Parts

ArcWorld 2000 Series - Flexible Workcells For Welding Large Parts

ArcWorld 6000 Series - Highly Efficient Workcell For Maximum Throughput

ArcWorld HC Series - Economic And Flexible Automation Solutions

ArcWorld LC Series - Economic And Flexible Automation Solutions

ArcWorld RS Series - Compact Indexing Welding Workcell

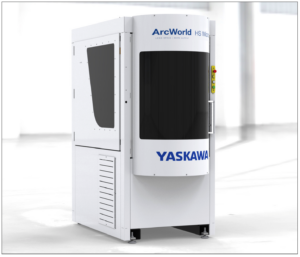

ArcWorld HS Series - Our Most Compact Welding Workcell

AR Series - Arc Welding Robots

GA Series - Highly Accurate and Versatile Robots

HC Welding Series – Human Collaborative Robots Robots

Designed to work safely with, or in the same workspaces as humans, these six-axis human-collaborative robots meet established safety standards.