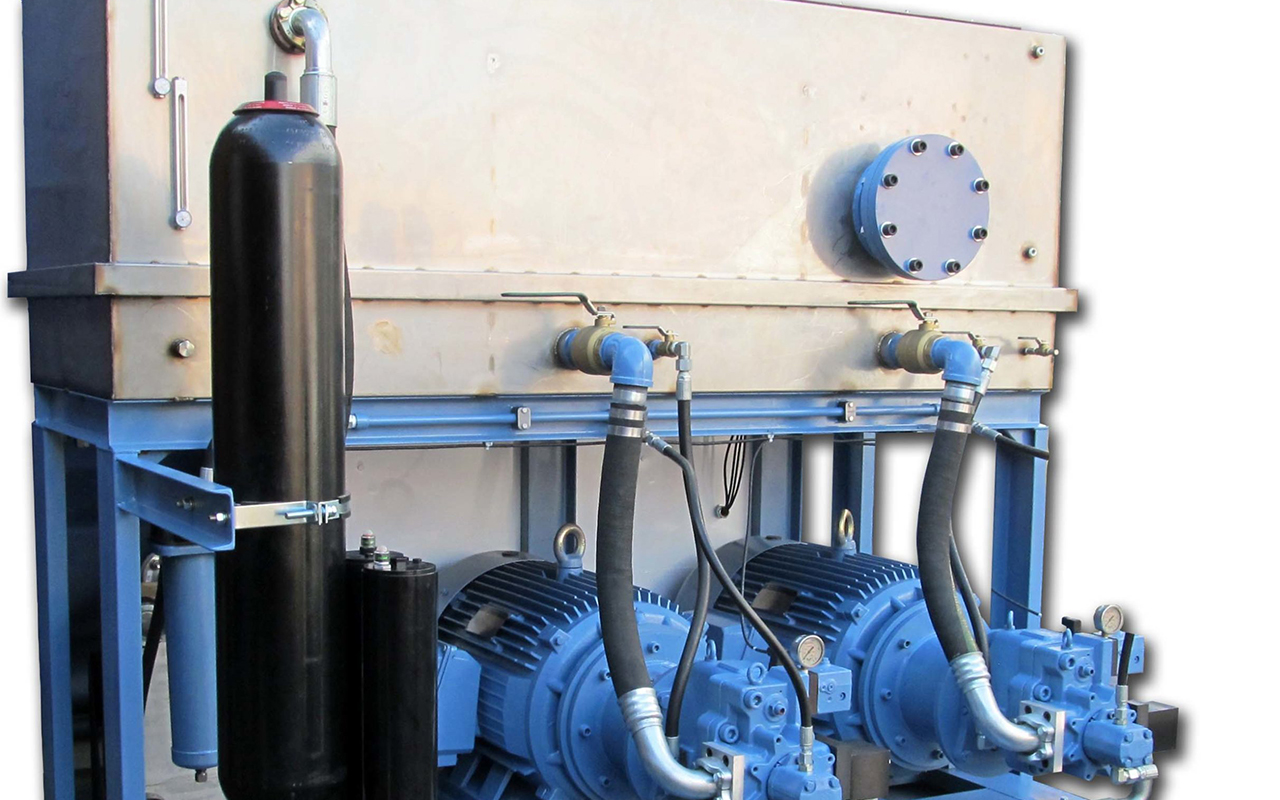

Improve Your Productivity with Pressure Measurement

Impact Automation’s Pressure Measurement offerings provide unmatched reliability and improved capabilities that help you to increase plant productivity and lower the total cost of ownership. We have a variety of products that provide a broad offering available to suit virtually every application.

Pressure Measurement Technologies

Improve Productivity with DP Flow Measurement

As one of the most common technologies for measuring flow, differential pressure (DP) flow has a long history of achieving high accuracy and durability. This measurement technology enables compensated flow, pressure, and temperature readings from a single flowmeter solution, in some cases eliminating the need for impulse lines. These flowmeters can be delivered pre-configured, leak tested, and ready-to-install, reducing installation time and costs while increasing overall plant productivity.

Differential Pressure Level Measurement

Differential Pressure (DP) Level Measurement uses pressure readings and specific gravity to output level. DP Level is a common measurement technique that is used in a wide variety of applications. Solutions include standard transmitter connections and integrated transmitters with direct or remote mount seals that can be configured in tuned, balanced, and electronic systems. Additional Wireless options are also available.

Pressure Gauge Innovations

Impact’s Pressure Gauge offerings are designed with proven sensor technology to help you reduce maintenance and improve safety. Providing up to 10 years of reliable readings, these solutions resist failures caused by vibration, overpressure and other extreme factors and monitors device health with a local indicator light.

Gain the Process Insight to Optimize Every Point

Impact’s pressure instrumentation provides solutions to critical measurement challenges even in the harshest environments. Make the most informed decisions for improved productivity, quality, energy management and safety.

Pressure technology solutions include capacitive, piezoresistive and other sensors to provide essential process data in differential, gage and absolute pressure applications. These sensors measure pressure, level, flow and derivatives by physically responding to the changes in process pressure, converting the physical movement into an electrical signal.

Multivariable measurement capability enhances operations by measuring static and differential pressure and temperature in a single device. With a variety of options, these devices include Ultra for Flow performance class, enhanced sensor matching, extended range sensor and a selection of protocols. Multivariable transmitters allow you to limit pipe penetrations, reduce wiring costs and reduce installation time.